FCI Is Building For A Bigger Future

[Notes From Behind The Gate]

September 24, 2024

Infill Thoughts

Today, coverage from our recent Eagle Ford frac field trip concludes with a report from our final stop of that journey – FCI Sand Operations.

Just in time too, because we are about hit the road again to bring you more firsthand observations. Later this week our research team will spend time gathering market intel in the Haynesville. And next week we head north to Wisconsin to lay eyes on several of the top Northern White Sand production facilities (sneaking that trip in just before it starts turning colder up there).

But first, here are thoughts on our recent FCI site visit in the Eagle Ford.

photo by Infill Thinking

This frac sand plant is situated just north of Campbellton TX, is well regarded by E&P customers for high quality sand, and has a big multi-faceted expansion project well underway.

In the photo below, shot from on top of the new wet plant, you can see both the new and the old at this location. New silos, a new dryer, new conveyors and new WIP areas are seen to the left of the old dry plant and old loadout facility on the right hand side of the image. This plant is getting a supersized overhaul.

photo by Infill Thinking

photo by Infill Thinking

Lots Of Construction In Progress…

During the time of our visit, the company was shipping sand from their original plant (old wash, dry, and 2 smaller loadout silos) while building their new state-of-the-art facility.

We observed construction crews working on at least 5 different projects on site simultaneously at FCI:

- new wet plant (purchased from a Kermit-area sand plant) was partially operating and in setup/testing/fine tuning mode (very close to being fully online)

- new dryer was installed and nearly ready to fire up, just waiting on connections

- two of the six new silos were vertical, with steel for the rest on location and the full foundation laid

- conveyors to move wet feed to dry plant and dry feed to silos were on location and being set up

- road construction was in progress for a new loop where trucks will enter and exit one-way for smoother traffic

Once construction is done, management plans to eliminate the original plant equipment. When the build-out is complete, we estimate this will be a Top 4 frac sand plant in the Eagle Ford by size. The company is clearly investing for the future here and gunning to be one of the top sources of frac sand in South Texas.

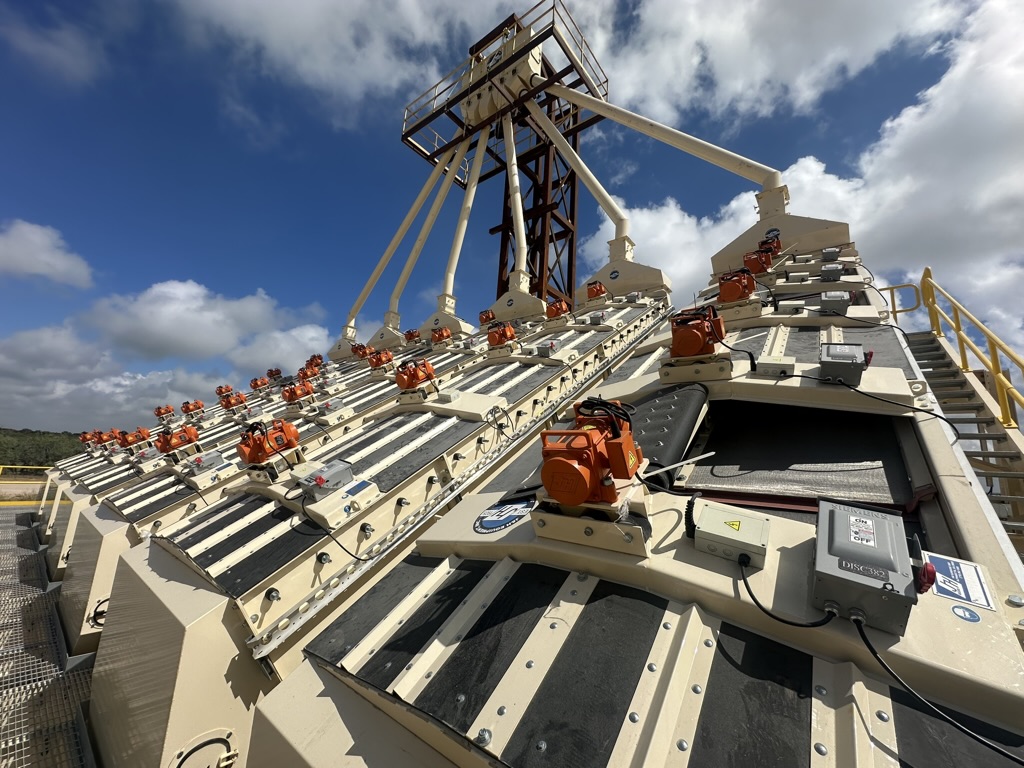

Vertical screens between dryer and silos; photo by Infill Thinking

Vertical screens between dryer and silos; photo by Infill Thinking

…With Some Nice Sand

Something that management really emphasized to us during our visit was the quality of the sand here.

Kevin Collier, FCI’s President, says that’s what he was initially attracted to when he found and purchased this site.

Management told us their independent lab tests show very high quartz purity here (99.8%) as well as below-average turbidity (250 ntu) and 7k crush.

Their quarry is pretty consistent, has decades of reserves, is 50+ feet deep in some places, and has no overburden. Yield is over 90% according to management.

FCI’s quarry operations – this site has extensive high quality reserves – and sharp eyes might see a simulfrac in the distance a couple miles outside their gates (squint a little and look for the twin wireline cranes); photo by Infill Thinking

FCI’s quarry operations – this site has extensive high quality reserves – and sharp eyes might see a simulfrac in the distance a couple miles outside their gates (squint a little and look for the twin wireline cranes); photo by Infill Thinking

Pictured below is the small wet plant waste pile we saw during our visit, accumulated over multiple production days. Kevin Collier dug out a handful and said that other plants would consider themselves lucky if their main stream was as good and clean as his waste stream.

Kevin Collier, FCI’s President, shows how clean his wet plant feed is; photo by Infill Thinking

The company has several dedicated customers right now who tell FCI they place a high value on this deposit’s quality. The quality of the sand, their location, and the improved scale and reliability we expect they’ll get out of the new supersized plant should make them a formidable competitor in Eagle Ford sand supply stack for years to come as they execute on their plans here.

Site Visit Observations

In the bullet points below are other notable field visit observations from our time on site in late-August:

- All current volumes they are able to produce are pre-contracted with 2 dedicated customers – one E&P, one pressure pumper

- Making only dry sand now – similar to their regional peers, FCI is willing to discuss damp sand sales but says customers aren’t looking for it at this time

- Say they routinely entertain requests from competitor mines interested in buying their sand

- Counting their verbal commitments, management says they’ll be sold out in 2025

- During our visit, FCI was averaging approximately 2,600 tons/day out of the gate with capacity expansion imminent

- Watch out for this location’s stated nameplate increase to 4 to 6mmtpa dry sand capacity after the projects are completed

- Construction timeline – management expects their capacity expansion to finish up in phases starting this month with the lion’s share of the new equipment expected to be up and running by early-2025

- Installing 8 wash lines with 250tph processing capacity each – hair cutting that a bit for yield, we think one could justify calling this a 6mmtpa stated nameplate facility if they complete the build according to plan (new wet plant was purchased from Hi-Crush Kermit)

- The plan is to convey finished dry sand from the dryer through their vertical screens and then on up to the silos at the front (this screening step managements sees as overkill given their sand quality but thinks it will give customers additional assurances in FCI sand quality control)

FCI President Kevin Collier walking towards his new dryer; photo by Infill Thinking

FCI President Kevin Collier walking towards his new dryer; photo by Infill Thinking

- 8 brand new silos going in for a huge loadout area that will offer drivers 6 lanes (2 of the silos hold 5k tons each, while 6 more will store up to 2.5k tons each)

- these silos were purchased from Buffalo Sand in NM

- Will target 140,000 tons in their wet WIP inventory stack

- Installing rapid decant technology and say it’ll take less than half a day for their wet feed to be dryer ready

- New dry plant will run on propane

- Fun fact: the silo pad cost the company nearly a million dollars to construct, but you get what you pay for and this pad has 5 feet of reinforced concrete over the top of that is 8 feet of compacted soil laid and tested 8 inches at a time – those silos are going to be rock solid!

FCI’s new dryer; photo by Infill Thinking

FCI’s new dryer; photo by Infill Thinking

Copyright © FCI Frac Sand 2022. All rights reserved. Designed by Austin 360 Marketing